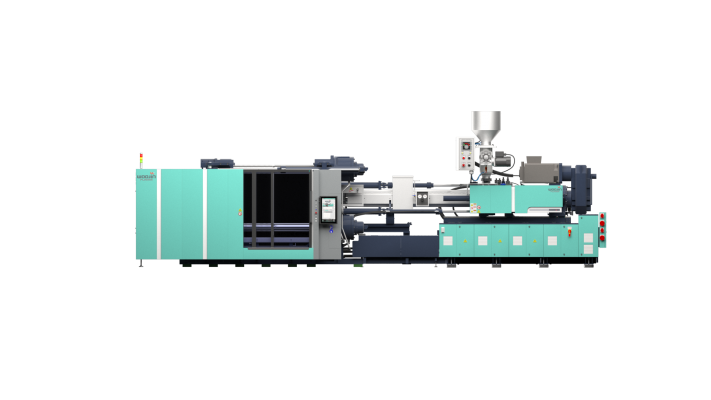

DL-A5(super-foam)

Premium super foaming direct locking series

360˚ VIEW

Two-platen direct low pressure physical microcellular foam injection molding machine

This is a foam injection mold that dissolves inert GAS under the threshold (less than 10 Mpa) into the molten resin to inject it into the mold, andutilizes the fine discharge of GAS.

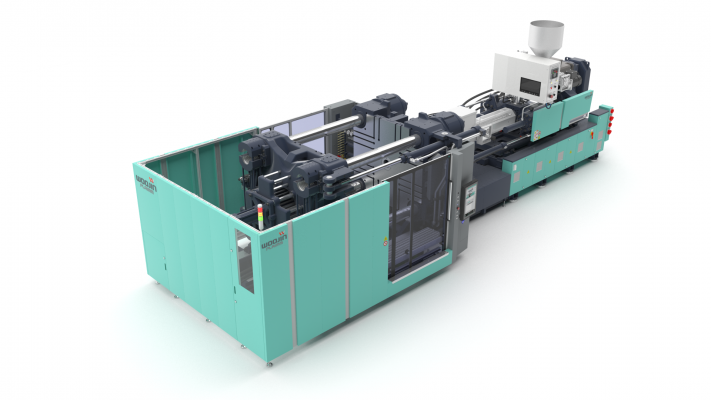

Clamping Unit

01. Platen Structure

· FEA finite.Increase mold installation weight by minimizing platen bending through

small method design (ver.2).

02. Maximize Space Utilization

· Space utilization is maximized by easy attachment of large molds in low ceilings and

narrow spaces (ver.2).

03. Increased durability

· The application of U-shaped screws and tie bars increases durability due to stress

dispersion effects.

04. Cycle Time Reduction

· Synchronized Half-nut locking controlling system to shorten the cycle time.

05. Location Precision

· Mounting a high-respond proportional valve on volumetric transfer part to increase

position precision.

06. Implementing reliable switching behavior

· Flexible opening and closing cylinder left and right configurations for stable opening

and closing operation.

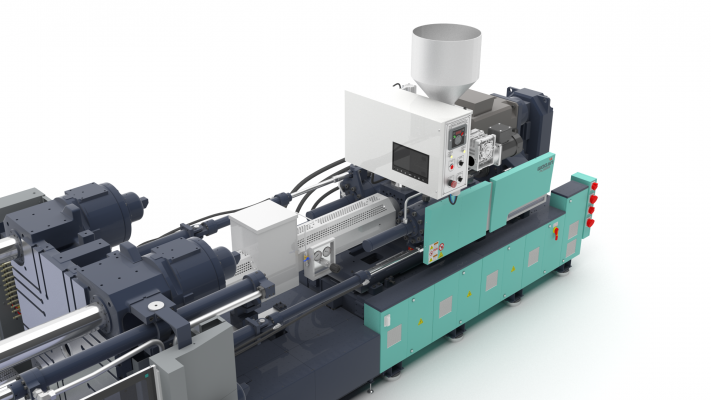

Injection Unit

01. Injection Back Pressure Closed-loop Control

· The user-set back pressure remains constant with closed-loop control.

02. Improved molding precision

· Prevent plate equilibrium problems caused by nozzle touch repetition to improve

molding precision.

03. Easy to manage screws and barrels

· It easy replacement and management of screws and barrels. (less than 1,300 tons)

04. Energy Saving

· Energy savings through maintaining parallelism and reducing friction through the

application of LM guides to injection beds and metering parts.

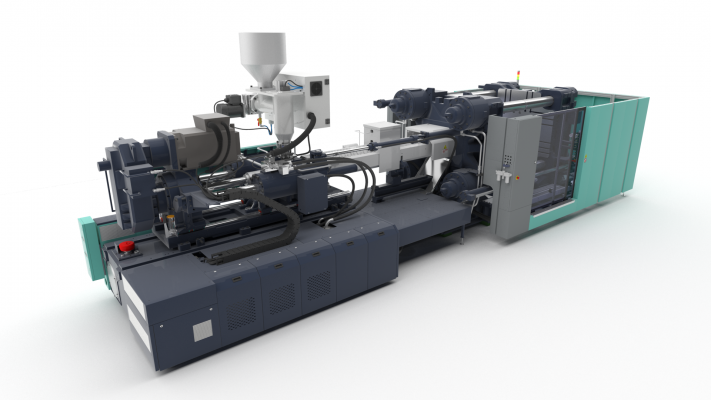

Hydraulic Unit

01. Oil Tank Special Coating

· Improving internal cleanliness through special coating inside and outside the hydraulic

block

· The specially coated oil tank prevents corrosion due to moisture and oil vapor

generation

02. Operating oil independent circulation

· Keep cleanliness and temperature constant through independent circulation

of operating oil (contribute to longer life of hydraulic oil and improved

durability of hydraulic components)

03. Prevent leakage of hydraulic pipes

· Seamless pipes, expansion tubes, and EO2FORM piping connections are strong against

high pressure and vibration to prevent leakage and damage.

04. Reduce energy and cooling water consumption

· Servo pump system reduces internal slippage to reduce energy and cooling water

consumption.