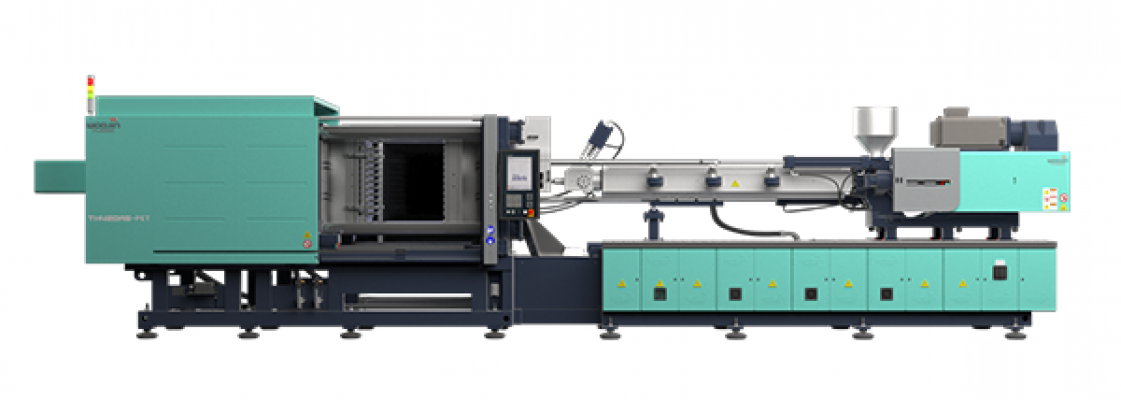

TH-A5 (PET)

PET pre-form special series

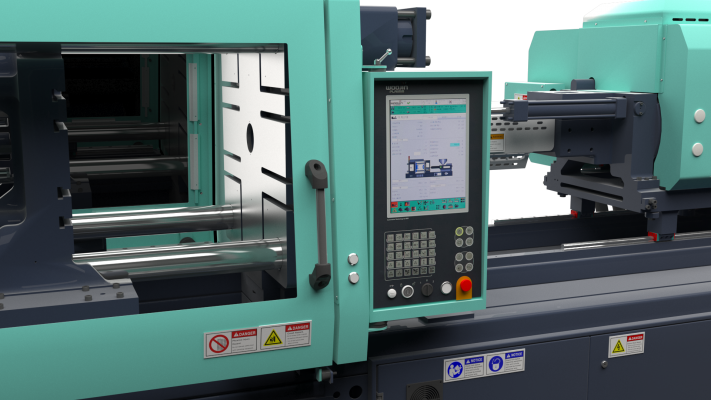

360˚ VIEW

Initiation of injection molding efficiency

This is a premium hydraulic power-saving injection molding machine that pursues highest

efficiency with ergonomic design that considers fast and stable operation and user

convenience.

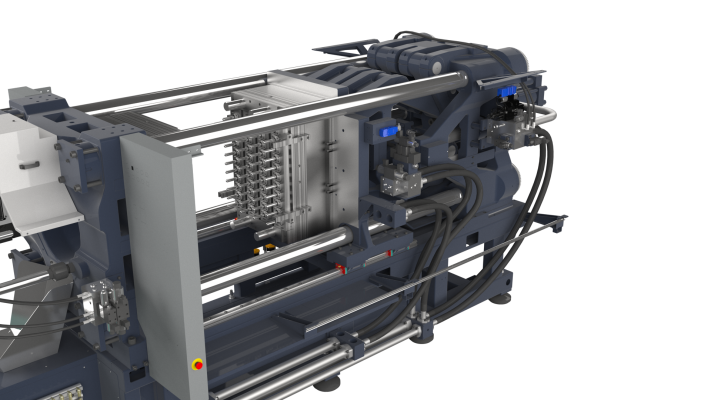

Clamping Unit

01. Increased durability

· Application of new toggle for fast opening and closing and clamp-type toggle pin

fixing to increase the durability.

02. Improved shape adjustment precision

· Encoder type control to improve mold adjustment precision.

(mold adjustment position control precision 0.01mm)

03. Maintain plate parallelism

· Maintain constant plate parallelism even with fast opening and closing operations.

· High energy efficiency with little movement friction during forward and

backward operation.

04. Transferring superior clamping force

· Superior volumetric power transfer in molds and uniformity of high surface pressure.

05. Wide tie bar spacing

· Equipped with a wide range of molds with increased tiebar spacing and clearances

compared to the same class.

06. High-response type opening/closing proportional valve

· Energy consumption reduction effect

· Reduction of dry cycle time

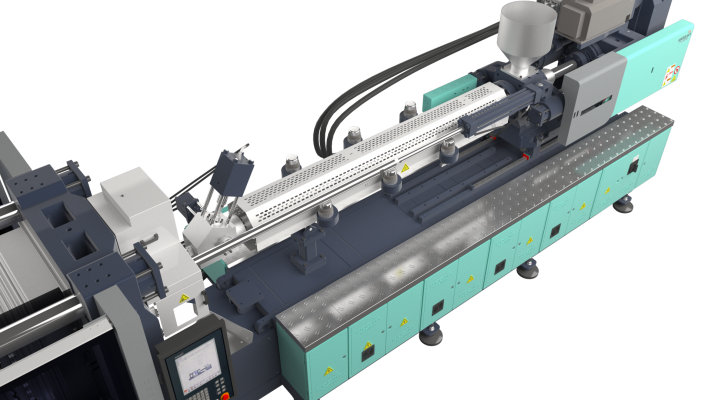

Injection Unit

01. Precise temperature control

· Precision temperature control with 10% or more improvement in plasticization

compared to zone and PID synchronous temperature control.

02. Securing stability

· Ergonomic design for user convenience and stability during nozzle touch.

03. Injection Back Pressure Closed-loop Control

· The back pressure set by the user is maintained consistently with closed-loop control.

04. Oil flow sound and oil leakage prevention effect

· The location of each cylinder oil of the hydraulic line is close to improve

responsiveness, and the integration of the hydraulic line prevents the flow and leakage.

· The close location of each cylinder of the hydraulic line improve responsiveness.

(Easy modulation)

05. Improve responsiveness and control capability

· Improving responsiveness and control capability by injection and forced retreating

independent structures;

06. Apply LM Guide

· Energy savings through maintaining parallelism and reducing friction through

the application of LM guides to injection beds and metering parts.

07. Back-pressure closed-loop control

· Homogeneous melting with product weight deviation of 0.2% or less

08. Holding pressure cylinder

· Effective and shortened cycle time by combination of plasticization during holding pressure.

09. High-mixed PET-only mixing screw

· Improved plasticization performance (L/D ratio of 25)

· Optimization of PET preform molding by applying exclusive mixing screw and AC servo motor for PET materials. (15% reduction in plasticizing time.)

· Heater cover fan installation to prevent accumulated frictional heat.

· Nozzle specification - Ø18, R33, Installation of barrel supporter

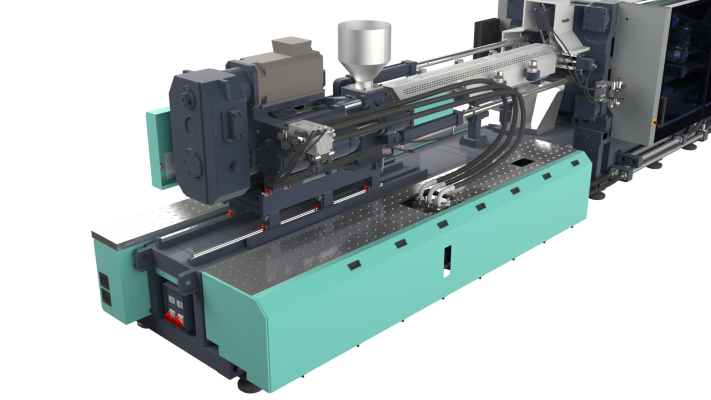

Hydraulic Unit

01. Reduce noise and improve space utilization

· Reduced noise and improved space utilization by integrating servo motors required

to drive the option of the injector.

02. Hydraulic oil independent circulation

· Keep cleanliness and temperature constant by Hydraulic oil independent circulation.

(contributes to longer life of Hydraulic oil and improved durability

of hydraulic components)

03. Improved internal cleanliness

· Special coating inside and outside the hydraulic block for improved internal

cleanliness and strong corrosion resistance.

04. Reduce energy and operating oil consumption

· High efficiency pumps and motors reduce energy and Hydraulic oil consumption.

05. Modular hydraulic core application

· Modular hydraulic core application facilitates scalability.

Controller (IMC 500/501)

01. Compatibility

ㆍWindows7 Embedded

ㆍOPC-UA (Euromap77)

ㆍGigabit Ethernet

ㆍUSB3.0, RS232

02. Specifications

ㆍDisplay : 18.5" / 24"

ㆍResolution: 768 x 1366 / 1080 x 1920

ㆍTouch screen: Projected capacitive

ㆍCPU : Intel Celeron G3900E 1.7GHz

ㆍRAM : SO-DIMM DDR3, 8192MB

ㆍMemory: Cfast 32Gbyte MLC

ㆍIP Grade: IP65(Front), IP20(Back)

ㆍMachine: TH-A5, TE-A5, DL-A5

ㆍLanguage: International language

Controller (IMC 400)

01. Compatibility

ㆍVxWorks Real-time processing system

ㆍOPC-UA(Euromap77)

ㆍEthernet 10/100Mbps, CAN Bus Port, USB Port, Serial Interface

ㆍEnergy Monitoring and CMS System

02. Specifications

ㆍDisplay: 15"

ㆍResolution: 768 X 1024

ㆍTouch screen: TFT Color Touch Screen

ㆍCPU : lntel atom E3815, 1460MHz

ㆍRAM : DDR3, 1GB, SDRAM

ㆍMemory: CompactFlash 32GB

ㆍIP Grade: IP65(Front), IP20(Back)

ㆍMachine: VHA, DL-A5, TH-A5, VHS

ㆍLanguage: International Language