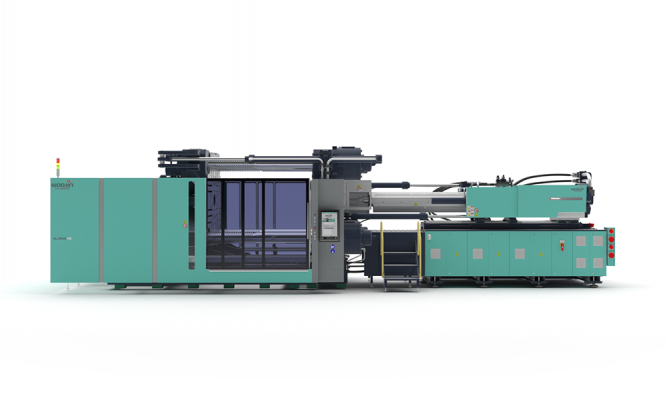

DL-A5

Premium two platen direct locking series

360˚ VIEW

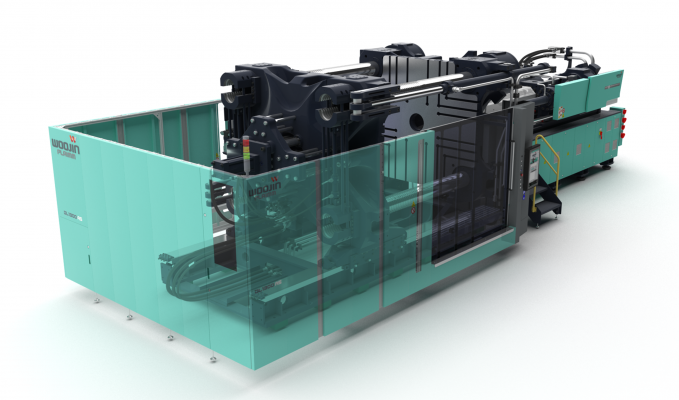

Clamping Unit

01. Platen Structure

· FEA finite.Increase mold installation weight by minimizing platen bending through

small method design (ver.2).

02. Maximize Space Utilization

· Space utilization is maximized by easy attachment of large molds in low ceilings and

narrow spaces (ver.2).

03. Increased durability

· The application of U-shaped screws and tie bars increases durability due to stress

dispersion effects.

04. Cycle Time Reduction

· Synchronized Half-nut locking controlling system to shorten the cycle time.

05. Location Precision

· Mounting a high-respond proportional valve on volumetric transfer part to increase

position precision.

06. Implementing reliable switching behavior

· Flexible opening and closing cylinder left and right configurations for stable opening

and closing operation.

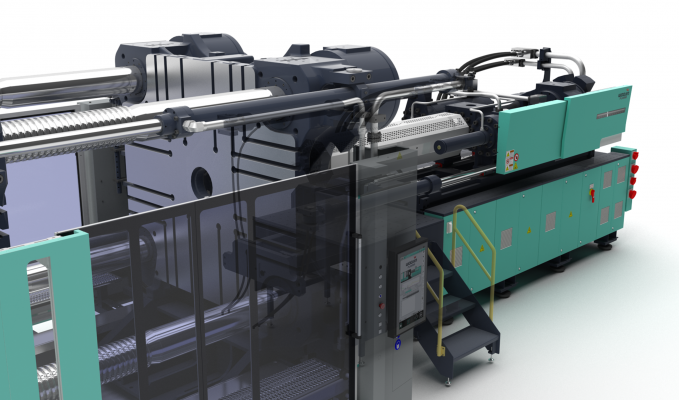

Injection Unit

01. Injection Back Pressure Closed-loop Control

· The user-set back pressure remains constant with closed-loop control.

02. Improved molding precision

· Prevent plate equilibrium problems caused by nozzle touch repetition to improve

molding precision.

03. Easy to manage screws and barrels

· It easy replacement and management of screws and barrels. (less than 1,300 tons)

04. Improve space utilization

· Unify servo drive boxes to maximize space utilization.

05. Energy Saving

· Energy savings through maintaining parallelism and reducing friction through the

application of LM guides to injection beds and metering parts.

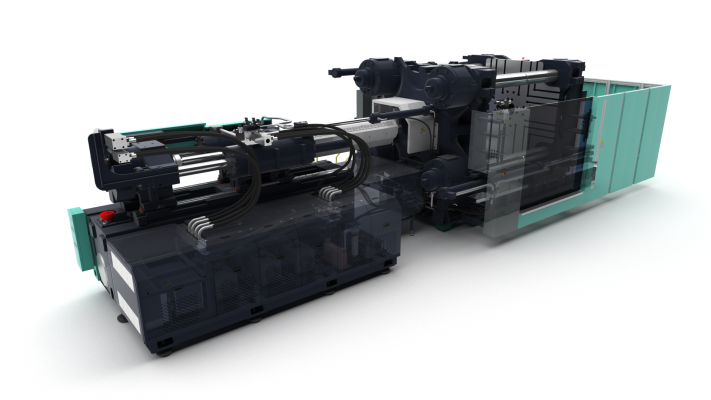

Hydraulic Unit

01. Oil Tank Special Coating

· Improving internal cleanliness through special coating inside and outside the hydraulic

block

· The specially coated oil tank prevents corrosion due to moisture and oil vapor

generation

02. Operating oil independent circulation

· Keep cleanliness and temperature constant through independent circulation

of operating oil (contribute to longer life of hydraulic oil and improved

durability of hydraulic components)

03. Prevent leakage of hydraulic pipes

· Seamless pipes, expansion tubes, and EO2FORM piping connections are strong against

high pressure and vibration to prevent leakage and damage.

04. Reduce energy and cooling water consumption

· Servo pump system reduces internal slippage to reduce energy and cooling water

consumption.

Controller (IMC 500/501)

01. Compatibility

ㆍWindows7 Embedded

ㆍOPC-UA (Euromap77)

ㆍGigabit Ethernet

ㆍUSB3.0, RS232

02. Specifications

ㆍDisplay : 18.5" / 24"

ㆍResolution: 768 x 1366 / 1080 x 1920

ㆍTouch screen: Projected capacitive

ㆍCPU : Intel Celeron G3900E 1.7GHz

ㆍRAM : SO-DIMM DDR3, 8192MB

ㆍMemory: Cfast 32Gbyte MLC

ㆍIP Grade: IP65(Front), IP20(Back)

ㆍMachine: TH-A5, TE-A5, DL-A5

ㆍLanguage: International language

Controller (IMC 400)

01. Compatibility

ㆍVxWorks Real-time processing system

ㆍOPC-UA(Euromap77)

ㆍEthernet 10/100Mbps, CAN Bus Port, USB Port, Serial Interface

ㆍEnergy Monitoring and CMS System

02. Specifications

ㆍDisplay: 15"

ㆍResolution: 768 X 1024

ㆍTouch screen: TFT Color Touch Screen

ㆍCPU : lntel atom E3815, 1460MHz

ㆍRAM : DDR3, 1GB, SDRAM

ㆍMemory: CompactFlash 32GB

ㆍIP Grade: IP65(Front), IP20(Back)

ㆍMachine: VHA, DL-A5, TH-A5, VHS

ㆍLanguage: International Language