DL-S

Performance to be completed based on rigid fundamental

Performance to be completed based on rigid fundamental

DL-S series is two platen hydraulic energy saving injection molding machine

that was completed by two fundamental principals of quality and efficiency.

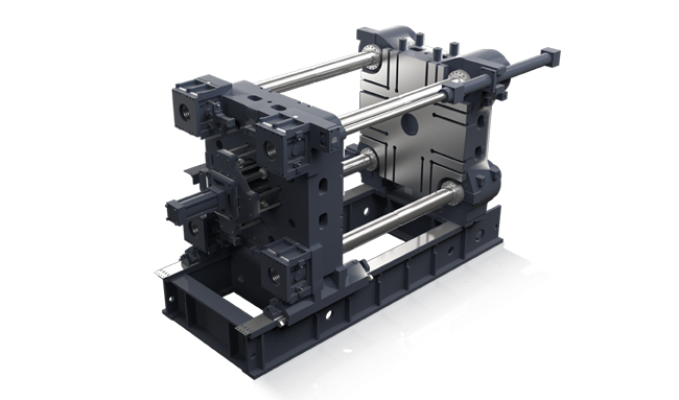

Clamping Unit

01. Rapid and precise movement can be realized by monitoring exact locking point by position sensor.

02. Stability of injection molding has been improved caused by prevention of releasing half nut during high pressure mold opening procedure.

03. Wide tie bar distance and enough daylight which are suitable for large size plastic parts.

· Excellent space availability compared with similar tonnage of toggle machine

04. Platen's parallelization can be maintained during low pressure molding closing procedure due to booster cylinder's bilateral symmetry placement.

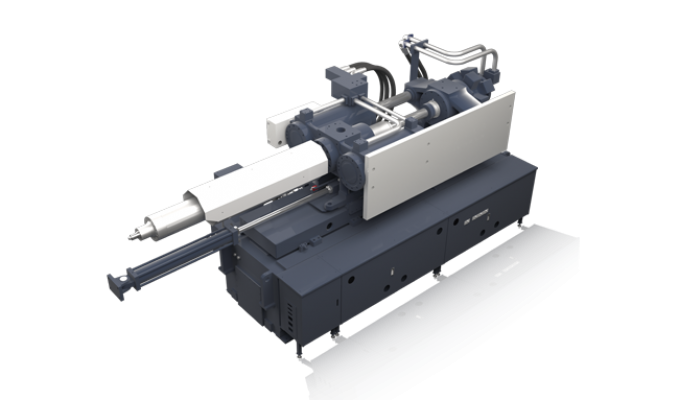

Injection Unit

01. The setting value of temperature is being controlled all the time. The deviation of temperature has been minimized and temperature rising is controlled equally on each section of barrel.

02. Precise control by servo pump system

03. Simultaneous movement is available during charging on fly period without additional hydraulic unit. Energy consumption can be reduced by high efficiency of power transmission (Optional electric charging)

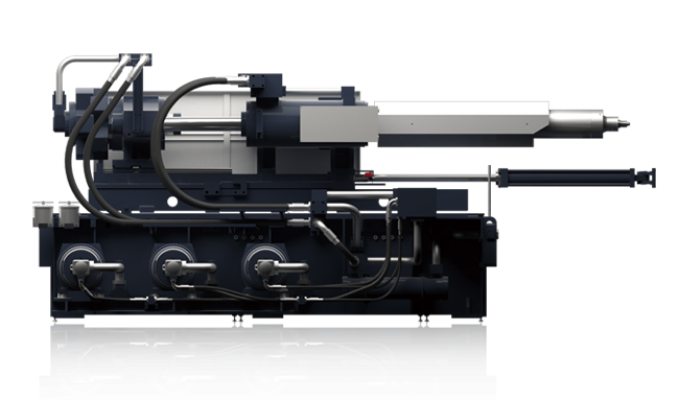

Hydraulic Unit

01. Realization of precise control through reduction of energy consumption and precise hydraulic oil flow due to motion control during holding pressure & cooling stage.

· Cooling water consumption reduced by 25%, Hydraulic oil consumption reduced by 15%

02. Special coating on hydraulic manifold for extending its life and anti corrosive feature.

Controller (GTB EVO)

01. Compatibility

ㆍModularized input /output device for easy scalability in the future.

ㆍOPC-UA (Euromap77)

ㆍDeploying the CMS System

02. Specifications

ㆍDisplay : 10.4"

ㆍResolution: 800 X 600

ㆍTouch screen: Resistive Touch Screen

ㆍCPU : Intel ATOM E660 1.3GHz

ㆍMemory: CompactFlash 2GB

ㆍIP Grade: IP65(Front)

ㆍMachine: DL-S