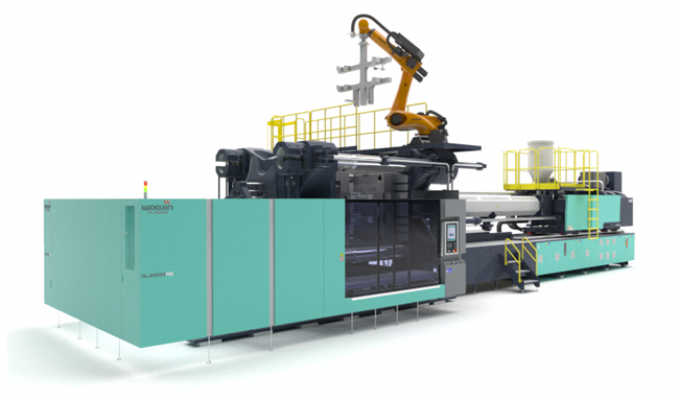

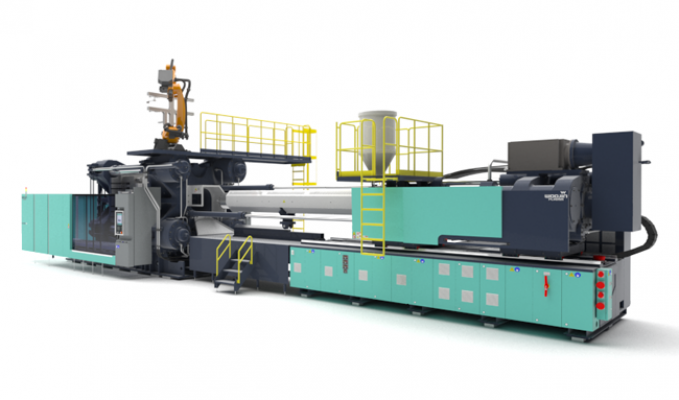

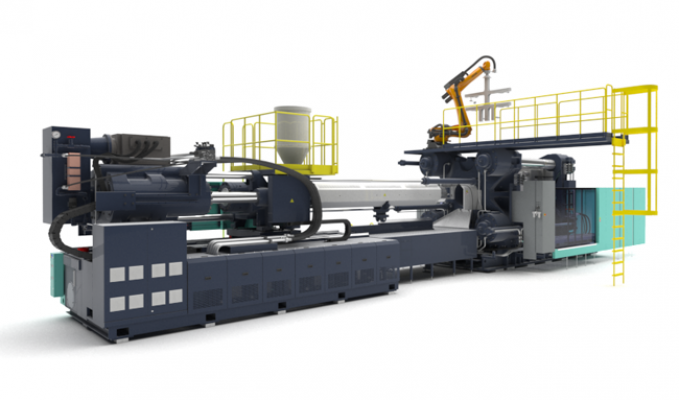

DL-A5(PALLET)

PALLET special series

360˚ VIEW

Two platen half nut type pallet injection molding machine

DL-A5(PALLET) is a fast and precise two-platen direct pressure power saving

injection molding machine with excellent space utilization with a beautiful and

practical exterior design, and a sturdy mechanism.

Clamping Unit

01. Platen Structure

· FEA finite.Increase mold installation weight by minimizing platen bending through

small method design (ver.2).

02. Maximize Space Utilization

· Space utilization is maximized by easy attachment of large molds in low ceilings and

narrow spaces (ver.2).

03. Increased durability

· The application of U-shaped screws and tie bars increases durability due to stress

dispersion effects.

04. Cycle Time Reduction

· Synchronized Half-nut locking controlling system to shorten the cycle time.

05. Location Precision

· Mounting a high-respond proportional valve on volumetric transfer part to increase

position precision.

06. Implementing reliable switching behavior

· Flexible opening and closing cylinder left and right configurations for stable opening

and closing operation.

Injection Unit

01. Injection Back Pressure Closed-loop Control

· The user-set back pressure remains constant with closed-loop control.

02. Improved molding precision

· Prevent plate equilibrium problems caused by nozzle touch repetition to improve

molding precision.

03. Easy to manage screws and barrels

· It easy replacement and management of screws and barrels. (less than 1,300 tons)

04. Improve space utilization

· Unify servo drive boxes to maximize space utilization.

05. Energy Saving

· Energy savings through maintaining parallelism and reducing friction through the

application of LM guides to injection beds and metering parts.

Hydraulic Unit

01. Oil Tank Special Coating

· Improving internal cleanliness through special coating inside and outside the hydraulic

block

· The specially coated oil tank prevents corrosion due to moisture and oil vapor

generation

02. Operating oil independent circulation

· Keep cleanliness and temperature constant through independent circulation

of operating oil (contribute to longer life of hydraulic oil and improved

durability of hydraulic components)

03. Prevent leakage of hydraulic pipes

· Seamless pipes, expansion tubes, and EO2FORM piping connections are strong against

high pressure and vibration to prevent leakage and damage.

04. Reduce energy and cooling water consumption

· Servo pump system reduces internal slippage to reduce energy and cooling water

consumption.