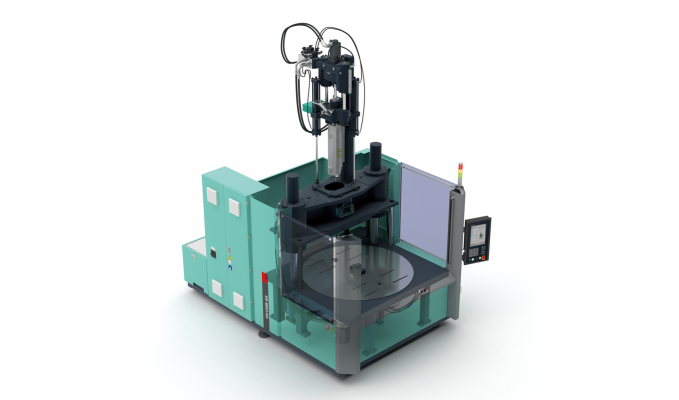

VH-RG5

Modern low-floor new vertical series

360˚ VIEW

Low-floor vertical power saving hydraulic injection molding machine

The low-floor vertical power saving hydraulic injection molding machine VH-RG5 is a Woojin

Plaimm’s solution to users, who are seeking the answers for manufacturing quality and

productivity.

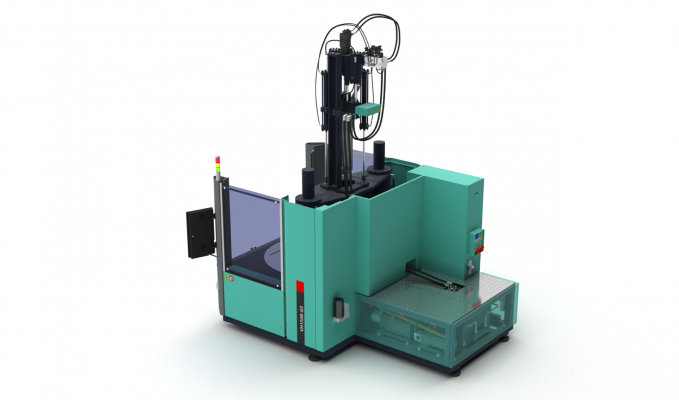

Clamping Unit

01. Rotation method by servo motor

· Precise control to determine acceleration, deceleration and position through digital

pulse control of positioning servo driver.

02. Application of low-profile shape structure

· Fixed turntable height at the floor regardless of tonnage.

· Easy attachment and detachment of mold.

· Easy to apply automation equipment.

03. Energy saving

· Energy saving using the weight of the upper plate and the weight of the mold.

· Optimization of self mold closing structure by applying a two-axis tie bar.

04. Easy to manage hydraulic oil

· Unlike general low-floor type, hydraulic oil management is simple because auxiliary

tanks are not required.

05. optimized working environment

· No need for a separate work platform.

Injection Unit

01. 2 axis injection cylinder / Independent suck back structure applied

· Improving responsiveness and control capability by independent injection and

suck back structure.

· Design optimized for balance and stability with a left-right symmetric structure

· Injection frame beam, LM guide applied to maintain parallel alignment.

· Improving vibration during injection, nozzle, and charging operation by applying

injection frame beam.

02. Horizontal injection device applicable

· Horizontal injection can be applied to the same clamping unit structure (option).

· Automatic height adjustment function of horizontal injection device.

(check the height value through the monitor)

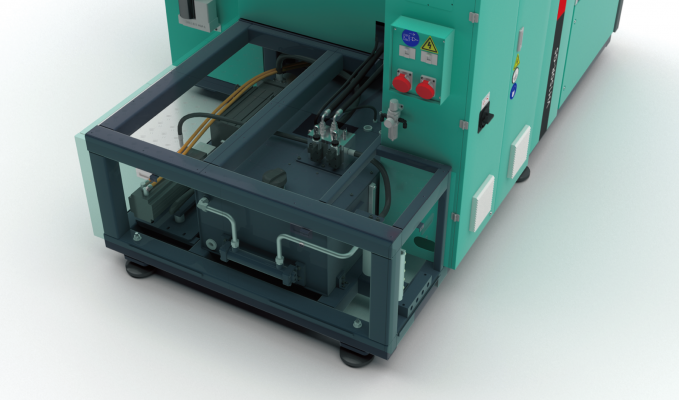

Hydraulic Unit

01. Reduce energy and hydraulic oil consumption

· Reduce energy and hydraulic oil consumption by applying high-efficiency

servo pump system.

02. Improved internal cleanliness and strong corrosion resistance

· Special coating inside and outside the hydraulic block for improved internal

cleanliness and strong corrosion resistance.

03. Ejector hydraulic circuit and hydraulic oil cooling

· Hydraulic circuit configuration for simultaneous operation of ejector during mold

closing, nozzle advance, and injection.

· Independent circulation method except ejector operation keeps cleanliness

and temperature constant.

(extending hydraulic oil lifespan, contributing to improvement of durability

of hydraulic parts)

04. Special painting treatment inside the oil tank

· Prevention of rust caused by moisture.

· Keep hydraulic oil clean.

· Extended hydraulic oil lifespan.

Controller (IMC 700)

01. Compatibility

ㆍEmbedded Linux

ㆍ10/100 Mbps Ethernet

ㆍUSB2.0, RS-232

02. Specifications

ㆍDisplay: 15"

ㆍResolution: 768 x 1024

ㆍTouch screen: 5-wire Resistive type

ㆍCPU : Cortex-A8

ㆍRAM : DDR2, 512MB

ㆍMemory: NAND Flash, 512MB

ㆍIP Grade: IP65(Front), IP20(BACK)

ㆍMachine: DL-G5, TE-G5, NC-G5, TE-NC, TB-G5, VH-RG5

ㆍLanguage: International Language