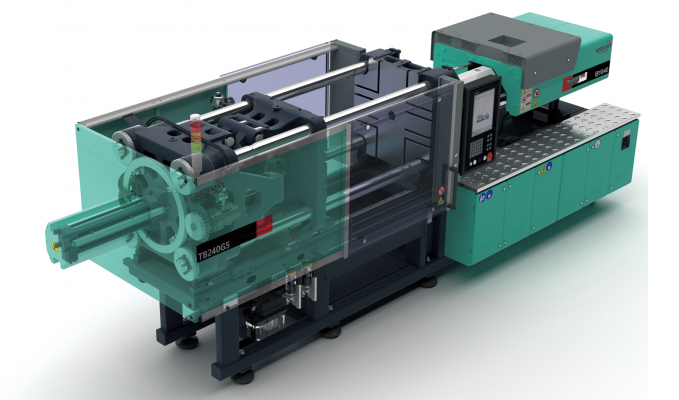

TB-G5

Modern new toggle hybrid series

360˚ VIEW

Standard of Global hydraulic injection molding machine

TB-G5 series is hydraulic energy saving injection molding machine with Korean technology

applied servo drive and controller and featuring excellent performance as well as energy

efficiency.

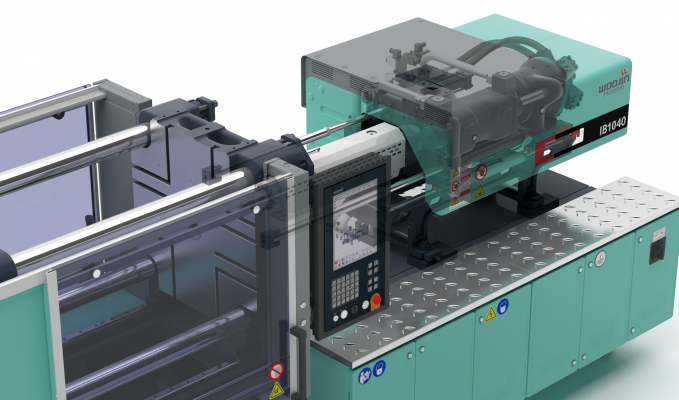

Clamping Unit

01. Integral center press clamping structure

· Apply integral center press clamping structure which is designed to transfer the

clamping force proportionally to the platen.

· By stabled inner pressure transferring to mold, prevent damaging platen and extend

the mold life.

· Maintaining the inner surface pressure equally to prevent the flash.

02. Apply L/M guide on moving plate

· Processing the L/M guide surface to Improve parallelism of clamping unit.

· Using less grease than previous roller type to sustain cleanliness.

· Apply high-load L/M guide to improve the precision.

· Enhanced durability to extend the part life and energy saving by friction reduction.

03. X shape platen design

· Optimized shape design ensures rigidity of platen and reduces inertia to manage

machine load and increase energy saving effect.

04. Platen control brake motor

· Keep user-set clamping forces and position values constant despite repetitive

clamping movement.

· Prevents clamping location moving from mold opening and closing movement.

Injection Unit

01. Dual pull nozzle touch cylinder

· Ensuring the stability of nozzle touch for improving molding precision.

02. Back pressure control by closed-loop

· Minimize the deviation between the user's setting value and actual figures.

(This can cause improved back pressure controlling capability)

03. Dual cylinder for injection

· Symmetry positioned design injection cylinders on left and right for improved stability

and responsiveness as well as enhanced balance.

· Minimize the mechanical shock and defect in molding process during the

injection cycle.

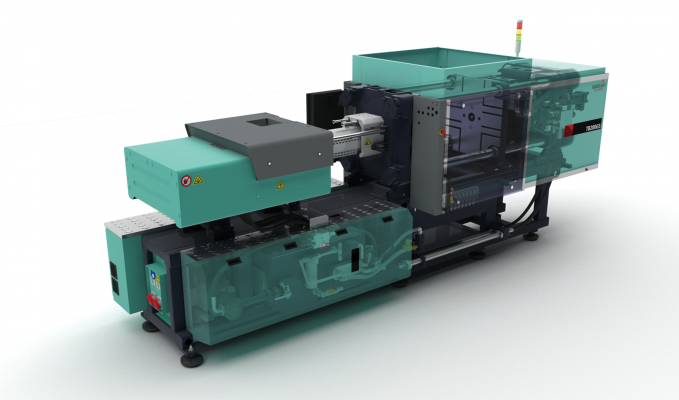

Hydraulic Unit

01. Type of oil tank circulation

· Independently equipped circulation line for oil cooling and filtering.

· Effective for enhance the hydraulic parts' durability, oil leakage prevention and oil's life

span extension.

02. Servo hydraulic system

· Reducing unnecessary motor operation by motion controlling system for less energy

consumption.

· Improved injection molding precision by accurate speed & pressure control through

servo motive system.

· Reduction of cooling water consumption for hydraulic oil.

03. High pressure system applied to hydraulic equipment

· High pressure hydraulic system has been applied from 140 bar to 175 bar.

· Reduced size of oil tank is equipped due to less oil requirement by applying high

pressure system.

04. Applying seamless pipe

· Chemical coated seamless pipe applied and non welding type fitting equipped.

05. Using ELIKA PIM pump with Helical gear type MARZOCCHI brand pump

· Featuring prompt response time and high accuracy with optimized efficiency plus low

noise (Up to 280ton machine).

Controller (IMC 700)

01. Compatibility

ㆍEmbedded Linux

ㆍ10/100 Mbps Ethernet

ㆍUSB2.0, RS-232

02. Specifications

ㆍDisplay: 15"

ㆍResolution: 768 x 1024

ㆍTouch screen: 5-wire Resistive type

ㆍCPU : Cortex-A8

ㆍRAM : DDR2, 512MB

ㆍMemory: NAND Flash, 512MB

ㆍIP Grade: IP65(Front), IP20(BACK)

ㆍMachine: DL-G5, TE-G5, NC-G5, TE-NC, TB-G5, VH-RG5

ㆍLanguage: International Language