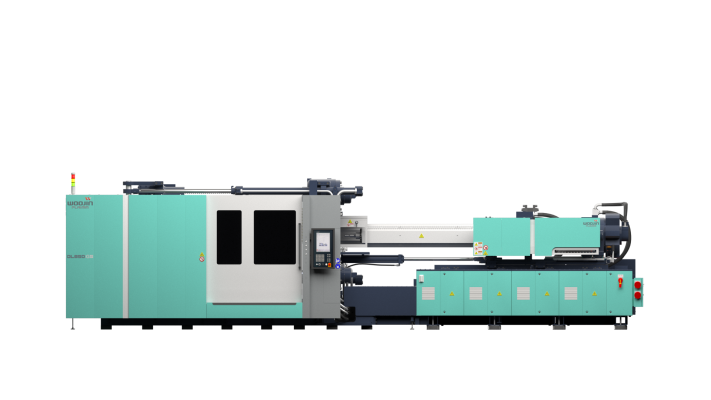

DL-G5

Modern two platen direct locking series

360˚ VIEW

Performance to be completed based on rigid fundamental

DL-G5 is two platen hydraulic energy saving injection molding machine that was completed

by two fundamental principals of quality and efficiency.

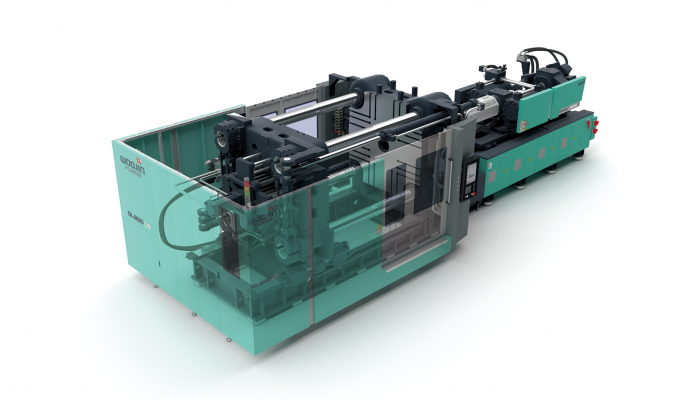

Clamping Unit

01. Platen structure

· By finite element method(FEM), minimized platen friction and increased mold weight

is allowed in clamping unit. (especially for 2300ton or bigger)

02. Durability increased

· Applying U shaped bolt and tie-bar is effective on dispersion of stress, so increased

durability.

03. Shortened cycle time

· Synchronized Half-nut locking controlling system to shorten the cycle time.

04. Precision of position

· Mounting high-respond proportional valve on clamping load part to enhance position

precision.

05. Stabled Open-close motion

· Organized clamping open-close cylinders on left-right side of clamping unit to stable

the clamping open-close motion.

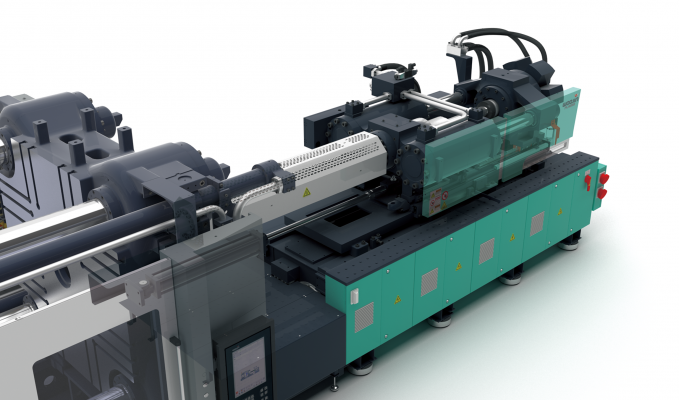

Injection Unit

01. Back pressure closed loop control

· User set back pressure is controlled by closed-loop control, so back pressure is

maintained in fixable condition.

02. Shortened cycle time

· Adding electric metering motor to enable of simultaneous motion for shortened

cycle time(option).

03. PID temperature control and Synchronous Heater temperature control

· Constantly control the set temperature value to minimize temperature deviation and

Synchronous Heater temperature controlling function to prevent nozzle carbonization.

04. Precise hydraulic control

· Precise control by servo-pump system.

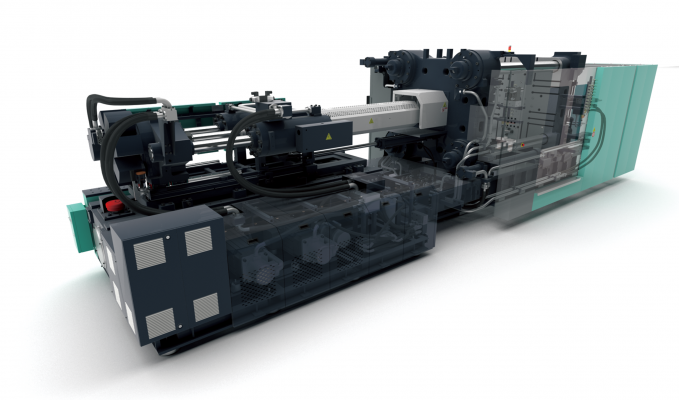

Hydraulic Unit

01. Special oil-tank coating

· By special in-out coating on hydraulic block to enhance inner cleanliness.

· Special coated oil tank prevent the corrosion by humidity and oil mist.

02. Independent Hydraulic oil circulation method

· Apply independent Hydraulic oil circulation method to sustain cleanliness and

temperature. (Extension of hydraulic oil life, improve hydraulic part durability)

03. Prevent hydraulic oil leakage

· Using Seamless pipe, pipe extension, EO2FORM pipe connecting method is strong

enough against high pressure and vibration, so it prevents oil leakage and damaging

to the pipe.

04. Saving energy and cooling water consumption

· Reduce internal slippage by servo pump system to save energy and cooling water

consumption.

Controller (IMC 700)

01. Compatibility

ㆍEmbedded Linux

ㆍ10/100 Mbps Ethernet

ㆍUSB2.0, RS-232

02. Specifications

ㆍDisplay: 15"

ㆍResolution: 768 x 1024

ㆍTouch screen: 5-wire Resistive type

ㆍCPU : Cortex-A8

ㆍRAM : DDR2, 512MB

ㆍMemory: NAND Flash, 512MB

ㆍIP Grade: IP65(Front), IP20(BACK)

ㆍMachine: DL-G5, TE-G5, NC-G5, TE-NC, TB-G5, VH-RG5

ㆍLanguage: International Language