Greener mono-material solutions to look out for flexible packaging

main text

Greener mono-material solutions to look out for flexible packaging

As one of the green and low-carbon plastic packaging, flexible packaging with mono-material structures is becoming increasingly popular in the industry.

In its Top Packaging Trends 2022, Innova Market Insights pinpointed “Monomaterial Mastery” as the second top trend, emphasizing the transition away from hard-to-recycle, multi-layer packaging to mono-material solutions that are ‘friendly’ to existing sorting facilities for recycling.

According to Innova Market Insights, 39% of global consumers say they recycle more than before the pandemic. Meanwhile, 52% perceive packaging that can be recycled as environmentally sustainable.

With increasingly stringent circular economy targets, the food and beverage market intelligence firm anticipates the shift to recycle-by-design packaging and rise in mono-material solutions across different types of packaging.

Mono-material packaging products with higher PCR content

Recycle-by-design solutions are more technically challenging in flexible packaging as a lot of flexible packaging is a combination of plastic/paper materials or laminates which is difficult to recycle due to the need to separate the components before sorting.

Therefore, suppliers are focusing their effort on developing mono-material alternatives to multi-layer packages. Thanks to the growth of recycled plastics, more mono-material flexible packaging is even enabled with recycled content feature for higher circularity.

Mono-material pasta packaging with PCR content

Garofalo, a major Italian pasta manufacturer, has introduced a packaging made by GT Polifilm and Polivouga using SABIC’s certified circular polypropylene (PP). The first pasta bags made from this new packaging was launched in Italian stores in March 2023.

The sustainable material is derived from chemical recycling and converted into a Biaxially Oriented PolyPropylene (BOPP) film for this application, which is said as the first mono-PP pasta packaging material in the market containing 30% of post-consumer recycled (PCR) content.

The PCR content in the bags is based on post-consumer used plastics, which is turned into pyrolysis oil in chemical recycling process. At SABIC, the pyoil is used in the production of new polymers with the same specifications as virgin plastics.

Polivouga, a vertically integrated Portuguese manufacturer of flexible films for packaging products, uses the SABIC PP 525PC grade from SABIC’s TRUCIRCLE portfolio of certified circular polymers to produce the basic BOPP film for the new circular pasta packaging.

GT Polifilm, a specialist in the production of flexible PP products for automated packaging in the food industry, adds a cast PP film to the BOPP film to create a mono-material structure, which is then converted to tailor-made pasta bags. The mono-PP bags can easily be recycled after use in existing PP waste streams.

More sustainable drawstring bag reaches the new level

With the enhanced EcoString bag, adapa Group, one of Europe's leading flexible packaging solutions companies, takes the classic drawstring bag for hygiene and cosmetic products to a new level.

The new and more sustainable EcoString bag contains 80% PCR content with both the bag and the drawstring made of easily printable polyethylene (PE). The familiar drawstring made of viscose is replaced by a plastic strap, while retaining its functionality.

The resulting mono-material packaging eliminates the need to separate the components for recycling and are thus fully recyclable. With film thicknesses from 32µm, they are among the thinnest products available in the market segment.

adapa also focuses on resource conservation in the production of the drawstring, which is made from edge trimmings from the production of the bags.

EcoString bags can be printed in up to 10 colors. Both the bag and the drawstring can be used for print communication. With their individual matte or glossy finish, they ensure a visually attractive product appearance at the point of sale.

Fully recyclable double barrier tube with high-percentage PCR

Polyfoil EcoPro is the newly launched mono-material double barrier tubes by Hoffmann Neopac, a global provider of high-quality packaging and dosing applications for pharma, beauty and oral care.

Comprising up to 60% PCR material, product contact compliant PCR is also incorporated in the shoulder and cap of Polyfoil EcoPro. The tube is fully recyclable in high-density polyethylene (HDPE) streams and has received product approval from the EU’s discerning RecyClass sustainability verification organization, as well as a Suez Grade A rating.

The body wall of 0.35mm of Polyfoil EcoPro represents a 30% reduction from the company’s standard Polyfoil tubes. The tube comes in diameters ranging from 30-50 mm with capacities of 50-200ml and are suitable for personal care and cosmetic products.

The tubes can be decorated with a variety of methods including inline digital and offset printing. They can also be combined with HDPE flip-top caps or recycled PE screw caps.

Polyfoil EcoPro tube marks the latest introduction in Hoffmann Neopac’s series of EcoDesign products. The debut follows several other bio-based tube launches including the PICEA Tube, comprised of 95% renewable material in the tube body and shoulder – including 9% spruce wood from wood waste in sawmills.

Cross-value-chain collaboration enables the circular economy

Collaboration across the value chain is set to catalyze the transition towards circular economy for plastic packaging as it enhances information exchange and technological innovation. When the plastic packaging industry moves towards the circular economy, more collaborative projects for mono-material products are anticipated.

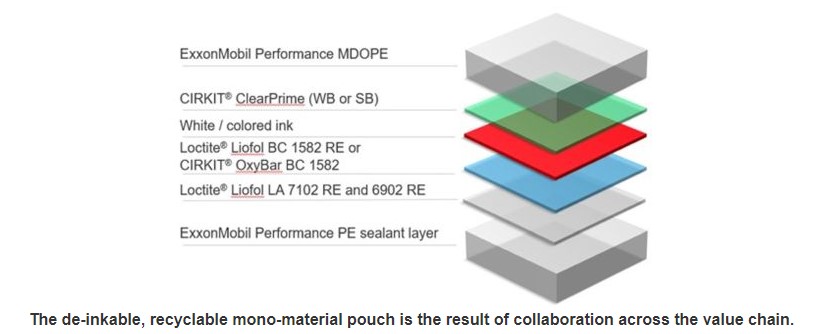

De-inkable, recyclable mono-material PE-pouch with barrier properties

A fully recyclable mono-material PE pouch has been developed with similar properties to barely recyclable multi-material laminated pouches. It provides a high oxygen barrier, good shelf-appeal and produces an almost colorless recyclate after removing printing ink and the oxygen-barrier coating layer.

The product is the result of a value chain collaboration of ExxonMobil, Henkel, Kraus Folie, Siegwerk and Windmöller & Hölscher (W&H).

Siegwerk´s delamination/deinking primer technology was applied on MIRAFLEX II, a W&H flexo printing press with a downstream unit. Applying industrial hot-washing conditions enables delamination and deinking of the pouch.

High oxygen barrier properties was achieved using the new Loctite Liofol BC 1582 RE 1-component barrier coating from Henkel and CIRKIT OxyBar BC 1582 from Siegwerk. The coating’s compatibility with recycling is confirmed by Cyclos HTP and it also meets Critical Guidance by American Plastic Recyclers (APR).

To improve recyclability, the partners used Henkel’s new solvent-free, 2-component polyurethane (PU) laminating adhesive. The system was designed for mono-material structures and is recognized for its compatibility with recycling as certified by RecyClass.

Outstanding packaging integrity was achieved using ExxonMobil’s latest generation of performance PE such as Exceed S and Exceed XP in combination with Exact materials in the sealant layer. The MDO-PE films was developed by ExxonMobil and Kraus Folie, employing ExxonMobil HDPE and Enable performance PE, and produced on their VAREX II extrusion line with inline MDO unit.

New mono-material PP-pouch fully compatible for mechanical recycling

Collaborating with value chain partners, Borealis has developed a new mono-material pouch containing over 95% PP. Thanks to the mono-material packaging format, it can help meet ambitious recycling and waste reduction targets.

In the extrusion lamination process, laminating PP cast and BOPP films yields mono-PP laminates with advantageous properties, including high barrier and stiffness for good sealing performance.

Using conventional adhesion lamination structures, pouch laminate materials containing approximately 90% PP can be obtained. However, the partners went beyond by boosting the share of PP to over 95%.

When processed in dedicated mechanical recycling streams for PP, the mono-material pouch yields greater volumes of high-quality recyclate fit for use in non-food, flexible PP packaging applications.

The high barrier pouch made of over 95% PP demonstrates good seal strength and hermetic sealing properties. Commercially available PP in Borealis’ extrusion coating and lamination grade portfolio offers stable processability and good laminate bond strength. These were used in tandem with tie layers contributed by Mitsui Chemical Group.

Jindal Films, a leading manufacturer of specialty BOPP films, contributed to this innovative solution for recyclable packaging. Profol, known for its innovative cast PP films and lightweight composites, produced the cast films. Huhtamaki Flexible Packaging contributed innovative laminates to the new pouch.

* Source : https://www.adsalecprj.com/web/news/article_details?id=63442&lang=1

* Edit : HANDLER