Chemists realize dissolving PET with electricity

main text

Chemists realize dissolving PET with electricity

Chemists at CU Boulder have developed a new way to recycle a common type of plastic found in soda bottles and other packaging. The team’s method relies on electricity and some nifty chemical reactions, and it’s simple enough that people can watch the plastic break apart in front of their eyes.

The researchers described their new approach to chemical recycling in the journal Chem Catalysis. The study helps tackle the mounting problem of plastic trash around the world.

“We pat ourselves on the back when we toss something into the recycling bin, but most of that recyclable plastic never winds up being recycled,” said Luca, assistant professor in the Department of Chemistry. “We wanted to find out how we could recover molecular materials, the building blocks of plastics, so that we can use them again.”

In the new research, she and her colleagues got one step closer to doing just that. The group focused on PET. In small-scale lab experiments, the researchers mixed bits of that plastic with a special kind of molecule then applied a small electric voltage. Within minutes, the PET began to disintegrate.

The team has a lot more work to do before its recycling tool can take a realistic bite out of the world’s plastic trash problem. But it was still fun to watch the waste, which can stick around in garbage piles for centuries, disappear in a matter of hours or days, said study lead author Phuc Pham.

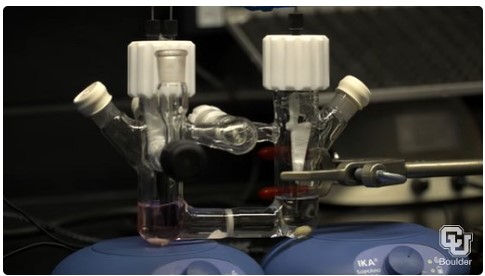

The researchers apply electricity to a solution containing ground up PET plastic.

Retrieve and reuse building blocks of plastics

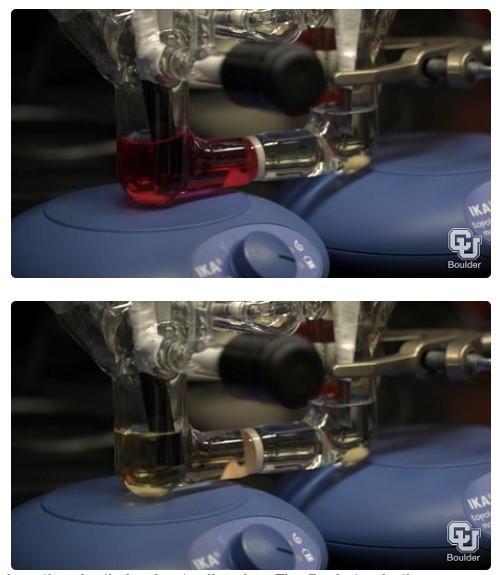

“It was awesome to actually observe the reaction progress in real time,” said Pham, a doctoral student in chemistry. “The solution first turns a deep pink color, then becomes clear as the polymer breaks apart.”

Luca said it’s a whole new way of thinking about the possibilities of trash. Methods like melting plastic waste or dissolving it in acid can alter the material properties in the process.

“You end up changing the materials mechanically,” Luca said. “Using current methods of recycling, if you melt a plastic bottle, you can produce, for example, one of those disposable plastic bags that we now have to pay money for at the grocery store.”

She and her team, in contrast, want to find a way to use the basic ingredients from old plastic bottles to make new plastic bottles. It’s like smashing your Lego castle so that you can retrieve the blocks to create a whole new building.

The solution turns pink as the plastic begins to dissolve. The final step in the proccess is exposing the solution to oxygen, which turns it yellow and eventually back to clear as the plastic fully breaks down.

Use electrolysis process

To achieve that, the group turned to a process called electrolysis—or using electricity to break apart molecules. Chemists, for example, have long known that they can apply a voltage to beakers filled with water and salts to split those water molecules into hydrogen and oxygen gas.

But PET plastic is a lot harder to divide than water. In the new study, Pham ground up plastic bottles then mixed the powder into a solution. Next, he and his colleagues added an extra ingredient, a molecule known as [N-DMBI]+ salt, to the solution.

Pham explained that in the presence of electricity, this molecule forms a “reactive mediator” that can donate its extra electron to the PET, causing the grains of plastic to come undone. Think of it like the chemistry equivalent of delivering a karate chop to a wooden board.

The researchers are still trying to understand how exactly these reactions take place, but they were able to break down the PET into its basic building blocks—which the group could then recover and, potentially, use to make something new.

Deploying only tabletop equipment in their lab, the researchers reported that they could break down about 40 milligrams (a small pinch) of PET over several hours.

* Source : https://www.adsalecprj.com/web/news/article_details?id=63009&lang=1

* Edit : HANDLER

- PreviousVietnam strives for FDI and supply chain lift 23.08.20

- NextPlastics part of Ohio's advantage in EV manufacturing growth, report says 23.07.21