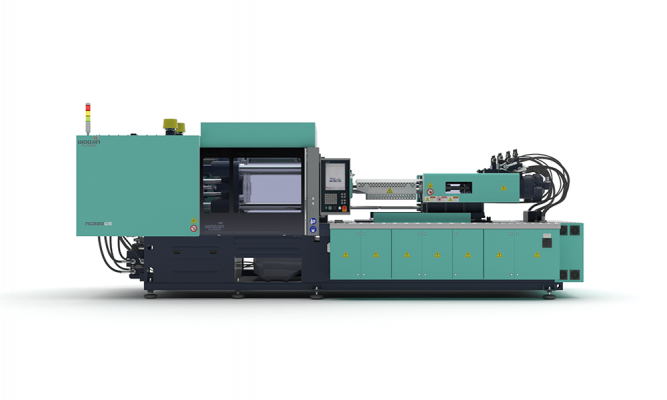

NC-G5

이색 이중의 수지를 'ONE-CYCLE'로

360˚ VIEW

이색 이중의 수지를 'ONE-CYCLE'로

NC-G5는 복잡한 성형제품의 생산 시 조립공정 및 후공정을 감소시켜 생산성 향상에 효과적인 이색 이중 절전형

유압식 사출성형기 입니다.

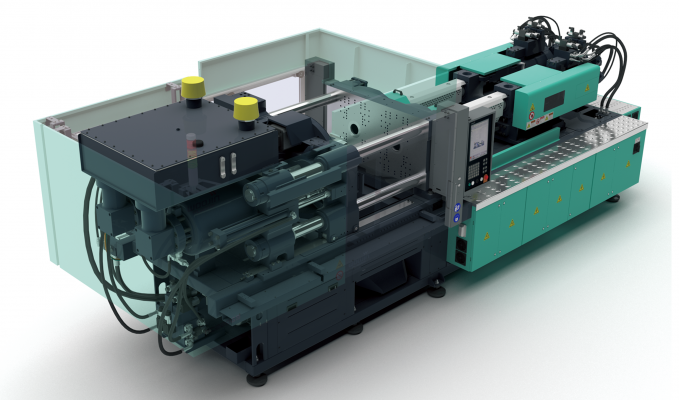

형체부

01. 넓은 타이바 간격

· 2개의 증압실린더 구조로 타이바 간격을 넓게 하였으며 형판구조를 개선하여

폭 넓은 금형 선택을 고려

02. 로킹실린더 및 근접센서 장착

· 형판 선회부에 로킹실린더 및 근접센서를 장착하여 선회 위치제어 향상

03. 2개의 증압실린더 사용

· 2개의 증압실린더를 사용한 직압식 구조로 두 금형의 중앙에 위치하여 사출 성형시 형내

평균압(투영 면적)이 다른 제품을 성형하여도 성형품의 정밀도에 영향이 적음

04. 이재질 성형 가능

· 다양한 금형 장착가능하며 이색, 이재질 성형 가능

05. 금형회전 전용 서보모터 장착

· 금형회전 전용 서보모터를 장착하여 빠른 회전속도 및 정확한 위치제어로 생산성 및

정밀성형 향상 및 서보펌프 시스템 적용하여 재현성, 에너지 절감율 향상

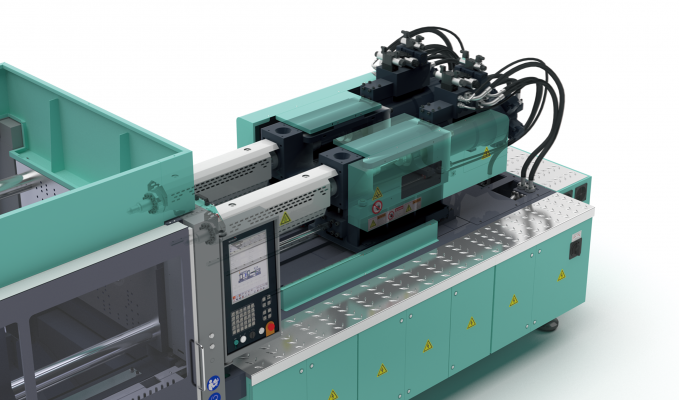

사출부

01. 2개의 수평 사출 유니트 구성

· 제품 특성 및 색상에 따른 2개의 수평 사출 유니트로 구성

02. 안정화된 가소화 실현

· 비례배압제어로 안정화된 가소화 실현

03. 정밀제어 용이

· 1차, 2차 측 분리제어로 제품 특성에 맞는 정밀제어가 용이

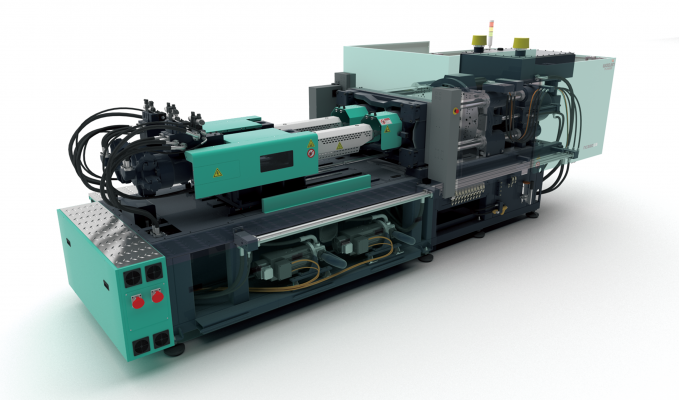

유압부

01. 에너지 및 냉각수 사용량 절감

· 서보 펌프 시스템으로 공회전을 줄여 에너지 및 냉각수 사용량 절감

02. 청결상태 및 온도 일정 유지

· 작동유 독립 순환방식으로 청결상태와 온도를 일정하게 유지

(작동유 수명 연장, 유압부품의 내구성 향상에 기여)

03. 부식 방지

· 특수 코팅된 오일탱크로 습기와 유증기 발생에 의한 부식 방지

04. 강한 내부식성

· 유압 블록 내,외부 특수 코팅으로 내부 청결도 향상 및 강한 내부식성

컨트롤러 (IMC 700)

01. 호환성

ㆍEmbedded Linux 운영체제

ㆍ10/100 Mbps Ethernet 지원

ㆍUSB2.0, RS-232 지원

02. 세부사양

ㆍ디스플레이 : 15"

ㆍ해상도 : 768 x 1024

ㆍ터치스크린 : 5-wire Resistive type

ㆍCPU : Cortex-A8

ㆍRAM : DDR2, 512MB

ㆍ메모리 : NAND Flash, 512MB

ㆍIP등급 : IP65(전면), IP20(후면)

ㆍ사용기종 : DL-G5, TE-G5, NC-G5, TE-NC, TB-G5, VH-RG5

ㆍ언어 : 국문 및 영문 (다국어 지원)