How auto suppliers are utilizing AI in auto manufacturing

main text

How auto suppliers are utilizing AI in auto manufacturing

Large suppliers including Bosch, Magna and Forvia are investing significant resources in AI tools

BOSCH

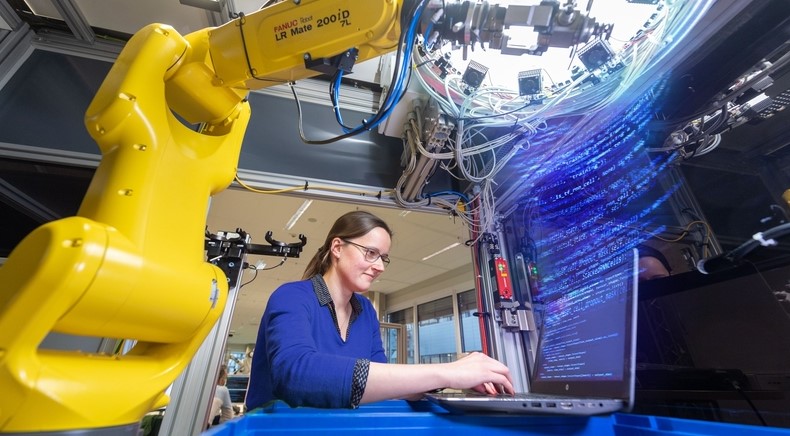

Suppliers such as Bosch, Magna and Forvia are utilizing AI to boost plant efficiency.

Suppliers increasingly view artificial intelligence as a means to become more efficient, reduce disruptive maintenance and better analyze new requests for business.

“If you think of where to apply AI in manufacturing, it can be very useful in pretty much every step,” said Benjamin Saltsman, Magna International’s director of data analytics, simulation and Internet of Things, during an Oct. 15 panel discussion hosted by the Society of Automotive Analysts.

Suppliers, particularly large ones, are investigating how AI, whether it’s generative artificial intelligence or more traditional machine learning applications, could help them become more efficient at a time when costs are rising, margins are thin and development times are shorter than ever.

Magna International Inc., like other large suppliers and automakers, sees generative AI as a particularly useful tool for maintenance, Saltsman said. Instead of flipping through manuals and other sources to fix a problem, workers might instead ask a generative AI tool what a solution might be, he said.

The Canadian supplier, North America’s largest parts maker, already utilizes AI to monitor the condition of some equipment. An employee at an office in Michigan, for example, remotely detected and recently alerted a plant in Ontario about an issue in one of its injection molding machines.

“They dispatched a maintenance person to the machine, and sure enough, the hydraulic pump was making an unusual noise and was about to go,” Saltsman said. “They were able to address the failure before it became catastrophic.”

Plants are increasingly automated and complex, and it is expensive for a company to have a machine down for an extended period of time. Because of that, many companies are opting to implement AI models for predictive maintenance instead of waiting for something to break, said Dan Hearsch, Americas leader of the automotive and industrial practice at AlixPartners.

“What artificial intelligence is essentially good at, whether it’s machine learning or generative AI, is pattern recognition that escapes humans,” Hearsch said.

Bosch developed AI-based software now used in 50 plants worldwide that identifies anomalies in the manufacturing process. An additional 20 factories use an AI-based system to detect scratches on surfaces, welding defects or other easy-to-miss issues in the parts it makes.

Bosch, the world’s largest supplier, also said AI data analysis has helped speed up production preparation of new lines by 15 percent.

Forvia, meanwhile, is investing in AI to significantly boost efficiency.

The company sees AI as a way to become leaner and more cost-effective, particularly for making parts for electric vehicles. Suppliers including Forvia are under pressure to keep costs in check as automakers look to make EVs more affordable.

“We’re targeting 50 percent efficiency gains, which doesn’t mean 50 percent less people, but maybe to do more with the same amount of people, especially in electronics, where it’s not so simple to find software engineers,” Forvia CEO Patrick Koller told Automotive News June 6.

Suppliers are also turning to AI to help them analyze requests for information and quotes they send out or receive.

“You can much better recognize patterns or recognize companies and see what they’re doing, and it gives you an additional layer of data to consider before sending out" a request for information, Hearsch said.

Despite the enthusiasm many suppliers have shown, others have concerns about security risks related to AI, Hearsch said. Companies want to know the data they input into any system is secure and cannot be accessed or changed by others, he said.

“Until we can really get used to and trust the underlying processes and security protocols, a number of CEOs will look at this with a hairy eyeball and walk tentatively forward,” he said. “The promise of it is tremendous. The risk of it is even more so.”

Suppliers should be meticulous about knowing exactly how different AI models might work and how their data could be used or put at risk, Hearsch said.

“You can use these tools to speed things up, but there’s still a process you need to go through,” he said.

* Source : https://www.plasticsnews.com/news/how-suppliers-are-utilizing-ai-auto-manufacturing

* Edit : HANDLER

- PreviousPotential European PFAS ban creates problems, opportunities 24.11.21

- NextUS sees ‘temporary' plastics trade surplus, report says 24.10.20