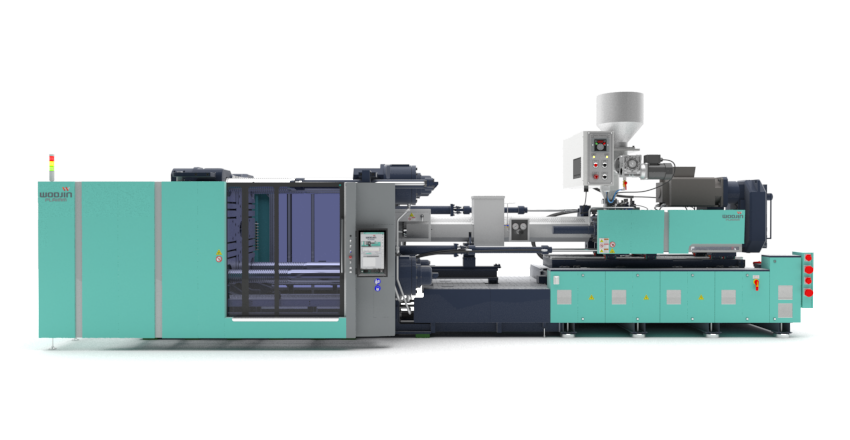

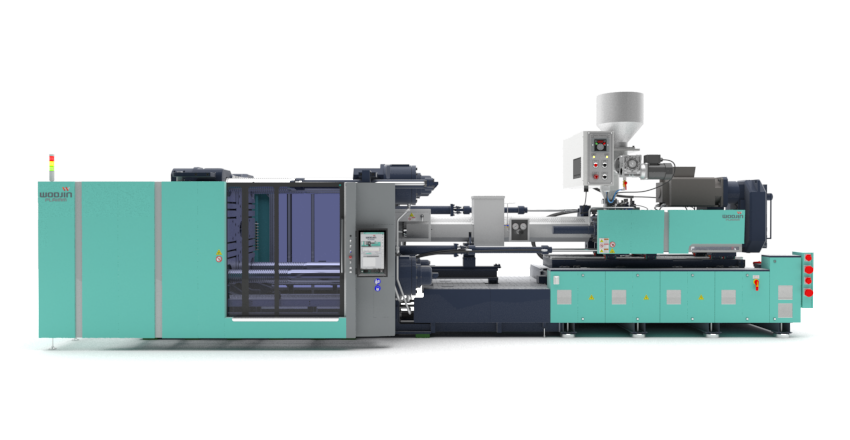

DL-A5 (Super-Foam)

Low pressure Physical Microcellular foam injection molding machine

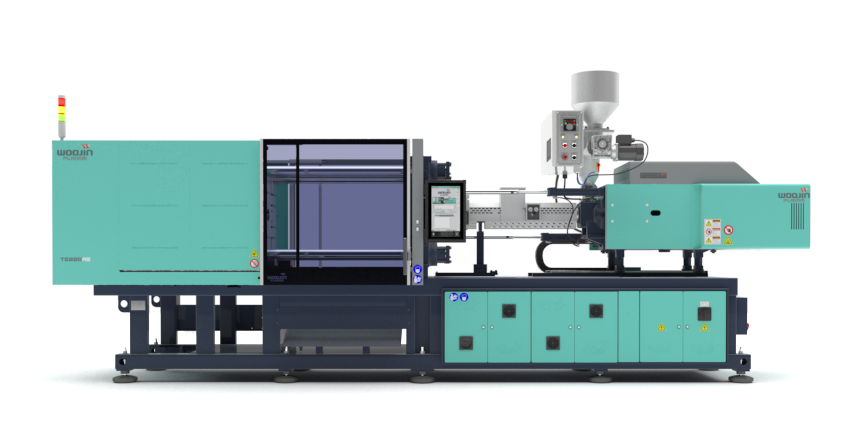

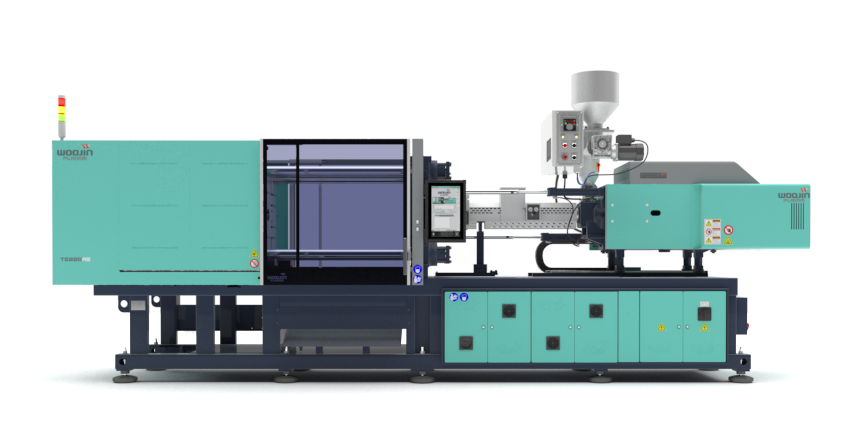

TE-A5 (Super-Foam)

Low pressure Physical Microcellular foam injection molding machine

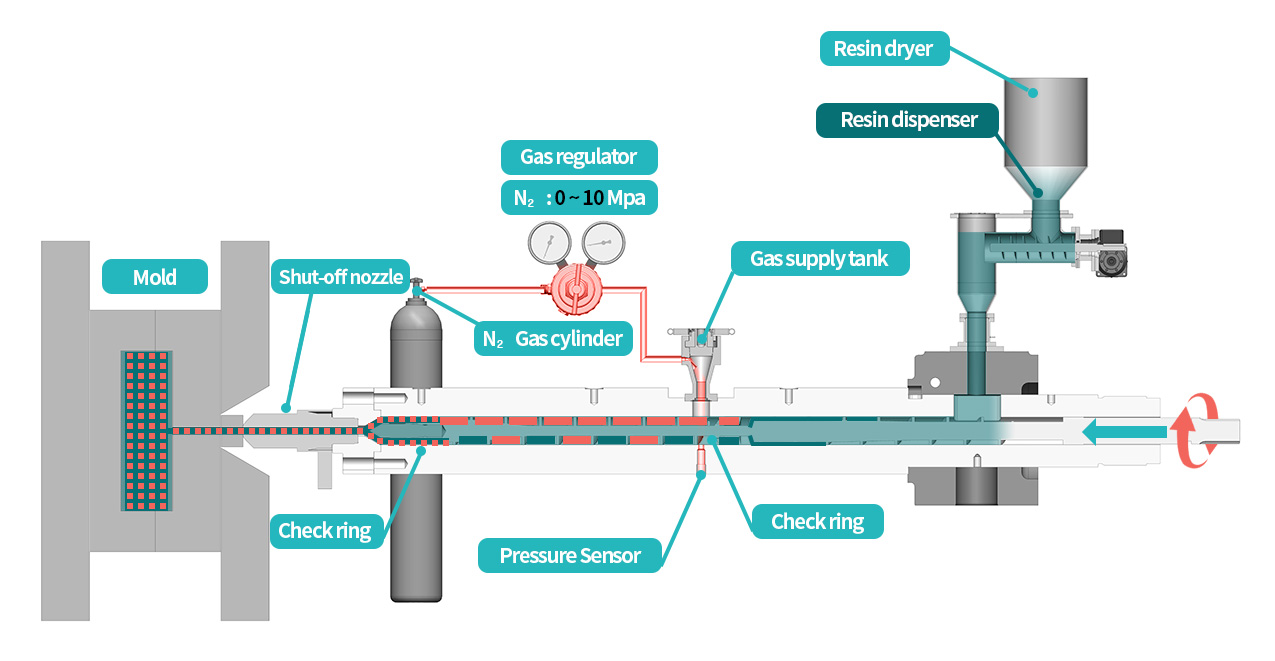

Schematic diagram of Super-Foam

Technology Introduction Super-Foam

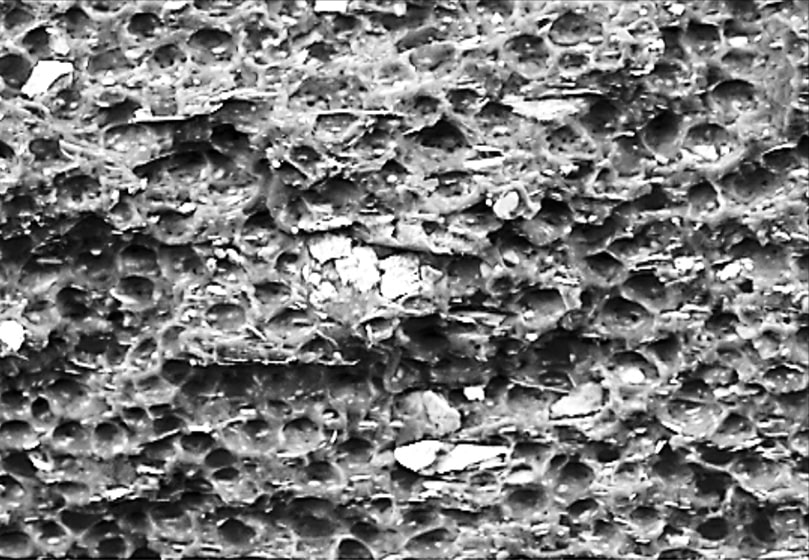

Porous body shape

A technology that produces bubble nuclei by dissolving and dispersing inert gas (nitrogen) in a polymer, and forming a porous product by decompression during the injection process to grow and stabilize the bubble nuclei.

Features and advantages of Super-Foam

Quality improvement

- Prevent shrinkage and deformation

- Improving the quality of injection molded products (removing shrink marks, increasing dimensional accuracy, reducing distortion)

Lighter weight (there is a difference in foaming rate depending on mold and resin conditions and injection method)

- 3-60% foam molding by controlling the ratio of applied resin and physical foam gas

Cost reduction

- Physical foam molding reduces the amount of raw materials required for injection molding to produce products with a small amount of raw materials.

Increased productivity

- Physical foam molding eliminates the holding pressure process, so the overall process time (cycle time) is shortened and productivity is improved.

Stability

- Continuous and stable foam injection equivalent to that of general injection is possible

Energy saving

- Energy saving effect due to lower heater temperature, clamping force, and injection pressure compared to general injection

Reduced maintenance cost

- Low-pressure gas and about 60-70% of the general injection clamping force are used, so the load applied to the machine is small.

- Resin is supplied to the gear, so the wear of the screw and barrel is low (the friction force is small)

- Because it uses low-pressure physical foaming agent, separate pressure intensifying device and control device are not required.

Universality

- A certain amount of physical foam molding is possible regardless of the type even without using a foam-only resin.

Other effects

- Insulation, thermal insulation, cold insulation, cushioning, buoyancy (buoy), sound insulation, sound absorption

Super-Foam test references

Intake manifold (automotive)

- Super-Foam

- Meterial : PA66 + GF40%

- 35% foam

- Raw material reduction and product weight reduction

- Cycle time reduction

- Relieve post-shrink deformation

Roof rack (car)

- Super-Foam

- Meterial : PA66 + GF40%

- 35% foam

- Raw material reduction and product weight reduction

- Cycle time reductio

- Relieve post-shrink deformation

Cooling fan (industrial)

- Super-Foam

- Meterial : PP + GF40%

- 10% foam

- Raw material reduction and product weight reduction

- Increased injection moldability

- Relieve bending

Control box (home appliance))

- Super-Foam

- Meterial : ABS

- 10% foam

- Product structure can be simplified

- Relieve post-shrink deformation

- Relieve bending

Show room operation

We are operating a showroom for the development and sample injection of Super-Foam (low pressure microphysical foam injection molding machine).